What is the Difference Between Straight and Spiral Router Bits?

When it comes to router bits, two commonly used types are straight and spiral bits. While they may appear similar at first glance, there are distinct differences between them that can significantly impact their performance and the results they produce. In this easy guide, we will explore the dissimilarities between straight and spiral router bits to help you understand which type is best suited for your woodworking needs.

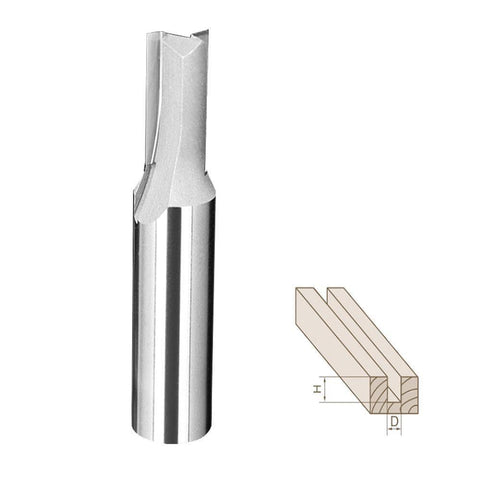

Straight Router Bits: Straight router bits are the go-to choice for many woodworkers due to their simplicity and versatility. As the name suggests, these bits have a straight cutting edge that extends directly from the base of the bit. Straight bits are primarily used for making straight cuts, creating grooves, dadoes, and rabbets, or trimming edges. They are available in various diameters and lengths, allowing you to choose the most suitable size for your specific woodworking tools.

Spiral Router Bits: Spiral router bits, on the other hand, feature a unique helical cutting edge that wraps around the bit in a spiral pattern. This design imparts distinct advantages to spiral bits. Firstly, the helical flute geometry of spiral bits helps to channel away chips and debris efficiently, resulting in a cleaner cut and reduced clogging. Additionally, the spiral cutting action generates less heat, which can be beneficial when working with heat-sensitive materials or preventing burning on hardwoods.

Differences in Cutting Speed and Finish: One notable difference between straight and spiral router bits is their cutting speed. Straight bits tend to cut more aggressively due to their direct cutting edge, making them ideal for quick material removal. However, this aggressive cutting action can sometimes result in a rougher finish, requiring additional sanding or smoothing. On the other hand, spiral bits provide a smoother cutting experience due to their spiral flute design, resulting in a cleaner finish that may require less post-processing.

Application Considerations: When deciding between straight and spiral router bits, consider the specific woodworking task at hand. Straight bits are excellent for tasks that require efficient material removal or cutting straight lines. They are suitable for dadoes, grooves, and general shaping. Spiral bits, with their superior chip evacuation and reduced heat generation, excel in tasks that demand precision and a high-quality finish. They are particularly useful for intricate designs, inlay work, or working with delicate materials.

Bit Selection Based on Material: The choice between straight and spiral router bits can also depend on the type of material you are working with. Straight bits are versatile and work well with various materials, including wood, plywood, and composite materials. Spiral bits, with their improved chip evacuation, are especially beneficial when routing dense or heat-sensitive materials such as acrylic, MDF, or solid hardwood.

Understanding the difference between straight and spiral router bits is crucial for achieving optimal results in your woodworking projects. Straight bits are versatile and excel at quick material removal and basic shaping, while spiral bits offer superior chip evacuation and a smoother finish, making them ideal for intricate work and delicate materials. By considering the specific woodworking task and material, you can confidently select the appropriate router bit type to enhance your woodworking experience and achieve the desired outcome.